Introduction

This article will deal with crown wire breaks, how to identify them, and the rejection criteria detailed within ISO 4309. A future post will cover the causes of fatigue.

What are fatigue breaks and how are they identified?

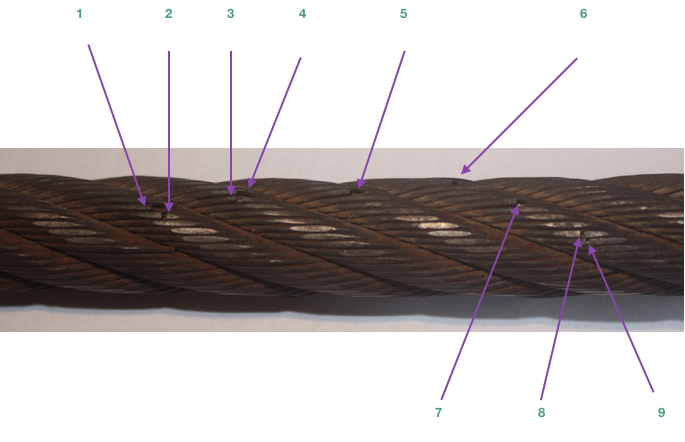

The individual wires in wire rope have a fatigue life limit, which when exceeded, will cause them to break. Typical external fatigue breaks are visible on the outside of the wire rope where the crown of the strand is in contact with the sheaves, drums and other contact points on the crane. They will predominate in the main working part of the rope.

A fatigue break will show as a flat-ended break in the wire (see the below image). The break will start as a hairline crack and will eventually tear away. A single fatigue crown wire break is generally not serious unless it is near the termination. So what are the limits and how do we know when to reject?

.png)

Typical fatigue broken wires shown on the strand crown of a wire rope.

ISO 4309 Rejection Criteria

ISO 4309:2017 details the limit of wire breaks over a length of 6 rope diameters (6d) and 30 rope diameters (30d). These values vary depending on crane design, single/multi-layered spooling on the drum, rope type, and the duty rating of the crane. Table 3 in ISO 4309 provides the discard criteria for single-layer and parallel-closed ropes, and table 4 covers rotation-resistant ropes.

The discard criterion depends on the number of load-bearing-wires in the outer strands of the rope (with a few exceptions). The Rope Category Number (RCN) provides a grouping system for the number of broken wires. Your rope manufacturer or supplier should provide this information.

These figures take into account the likelihood of having internal wire breaks as well. So ropes that are less likely to have external wire breaks such as Lang’s Lay will have a lower limit than ordinary lay ropes.

The following example details a 20mm 6x36 ordinary lay wire rope working in steel sheaves on an M1-M4 duty classification crane. In this rope, we have a total of 216 load bearing wires in the outer strands. The following discard criteria apply in this scenario.

- Broken Wires over a length of 6d (120mm) - 9

- Broken Wires over a length of 30d (600mm) - 18

The following table provides three illustrative examples of the number of broken wires and the condition of the rope as per ISO 4309:

| 0-6d | 6-12d | 12-18d | 18-24d | 24-30d | Total | Discard |

|---|---|---|---|---|---|---|

| - | - | 9 | - | - | 9 | Yes |

| 4 | 4 | 4 | 3 | 3 | 18 | Yes |

| 4 | 4 | 2 | 2 | 3 | 15 | No |

In the first row of the table, we see 9 broken wires within a single 6d section of rope. The rope should be discarded immediately.

In the second row of the table, we see 18 broken wires spread out along the entire 30d section. Like in the previous row, the rope should be discarded immediately.

In the third row of the table, we see 15 broken wires spread out along the 30d length. Although the rope is certainly very close to discard, you may have a short time frame in which you can delay replacement.

It should be noted that these are guidelines only and an inspector may decide based on his knowledge and experience to discard even though the number is below that detailed in ISO 4309.

This picture shows 9 visible broken wires within 6d and therefore has reached discard.

Conclusion

Thanks for reading our article! We hope you found it useful!

We have detailed how to identify fatigue broken wires and how to apply the relevant numbers detailed in the ISO 4309:2017 tables. It is important that you know what the rope is, the configuration of the crane that the rope is fitted to in order to determine the correct discard values held within the ISO 4309 tables.

If you enjoyed the article, give our LinkedIn page a follow so you can keep up with our updates by clicking the button below!

Again, thanks for reading,

The Rope IQ team.

Want to find out how Rope IQ can automate this process?

Request a quick 30 minute demo to find out.

Request a Demo